7 Simple Techniques For Hardwood Flooring

Wiki Article

More About Flooring Installation

Table of ContentsHow Laminate Flooring can Save You Time, Stress, and Money.About Installing Laminate FlooringThe 8-Minute Rule for Flooring StoresThe Ultimate Guide To Hardwood Flooring CostNot known Details About Flooring

Pour Component A right into Component B. Blend extensively up until the fluid is homogenous. Step 12: Wait for the Reaction Time Dependent upon temperature level, enable the epoxy to respond for the suggested time on the container. Do not rip off on this action or else you will certainly have a non-hardening sticky mess.The epoxy obtains taken in into the concrete pores as well as will shed its gloss if it is not used hefty sufficient. Action 16: Spray on Flakes Attempt to spread the flakes as high and also thin as possible for a light arbitrary pattern. hardwood floor installation. The flakes not only include an attractive surface area pattern however they likewise include some slide resistance to the flooring.

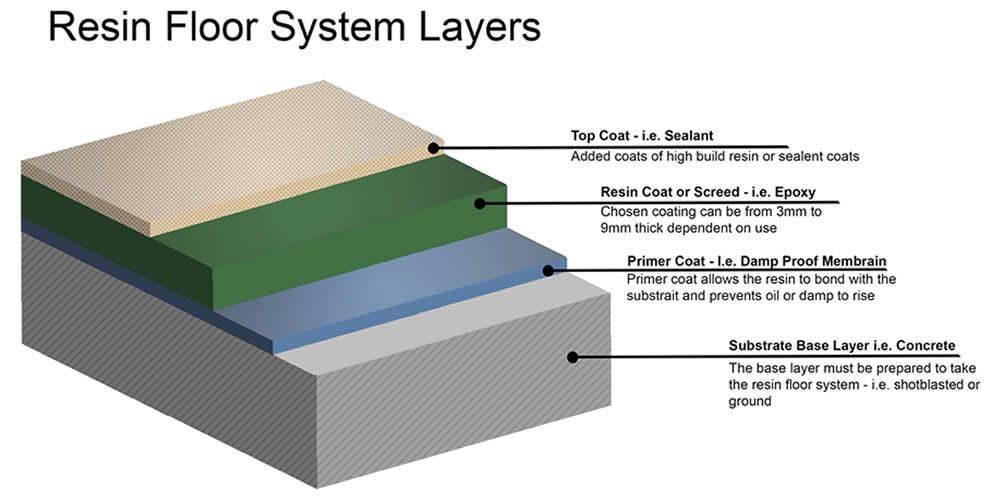

These examinations might include Calcium Chloride or Relative Humidity testing to determine the wetness content of the piece or contamination. Based upon the details found from these tests as well as onsite sees, the area is prepared using media blowing up, diamond grinding, jack hammers, and cracking guns. If slabs are established to be polluted with oils, de-greasing may additionally be required to attain correct bond.

Additionally, Stonhard's department Stonkleen provides cleaning items that are difficult on dust and spots, simple to use, lasting, and also created to preserve Stonhard seamless flooring systems.

A Biased View of Vinyl Flooring

Also the finest laid concrete floorings will certainly begin to break down and weaken in time. This can create splits, divots, and also chips to appear in your concrete floor. With a, your concrete will certainly be secured and also secured from the elements that can cause damage to your concrete while giving you a very easy to tidy and beautiful flooring.For a much deeper clean, you'll wish to mop your floorings with straightforward mix of ammonia and water. It's best to prevent any kind of soap mixtures as these can leave a film which can trigger your floors to become alarmingly slippery. show a bit more deterioration, and require even more maintenance so we usually recommend this kind of look in locations which will certainly get brushed up usually.

Some epoxy flooring contractors have actually even avoided installing them. They'll state it's as a result of the preconception, "metallic epoxy layers resemble a shag carpeting, they'll be gone in a few years" but it's really since they do not wish to have a floor failing and also humiliate themselves. Amiiright? Don't stress, we have actually installed thousands of metallic epoxy floors and even consisted of great post to read a DIY metallic epoxy garage floor for this post.

The Basic Principles Of Flooring

Just How To Install Metallic Epoxy Floors 8 hours and also 18 mins How To Mount Metal Epoxy Floors Action 1: Obtain Devices And Products Metal epoxy floorings require a whole lot of tools to set up if you desire to do it (flooring installation). The 3 biggest hurdles are surface area prep work and, blending and also application, (which each have regarding 20 steps).Some people pick not to do a real grind on the concrete and will certainly choose to pressure laundry or media blast the concrete, but honestly, you are establishing on your own up for failing. If you are going to do that, just utilize concrete paint and also call it a day since the metallic shade epoxy won't genuinely bond to the concrete substrate unless it is ground down as well as permeable.

Most remain in the 8 to ten-pound range yet some promote that they can withstand as much as 25 pounds. If there is any type of doubt or issue of wetness in the concrete it is 100% suggested to conduct wetness readings in different locations of the concrete. Or else, every one of your job will be for absolutely nothing.

Remember to use spiked shoes when using an epoxy dampness barrier as well as make use of a 3/8" or mohair roller. Back roll the whole surface area to ensure also circulation of the product. This is the strong color skim coat so it's not essential that it is best. Just even insurance coverage of the dampness obstacle at the manufacturer's suggested thickness (mil).

Not known Facts About Flooring

It is extremely important that the floor is as clean as feasible to avoid unattractive "comets" from appearing in the metallic epoxy application. Step 6: Mix Metallic Epoxy In order to have your metal epoxy covering come out really nice, you need to blend both components An as well as B epoxy in addition to the metal pigment.As we stated over if you want a 3 shade metallic epoxy floor that is 60% black metal pigment, 20% red metal pigment, and also 20% silver metal pigment, you'll have to have several various jugs where you proportionately blend your metallic pigments prior to laying them down on the floor.

Pour out what is mixed in the pail as well as do not tip the pail leaving it on the flooring. Don't risk having some component A that stays with the inside of its container and has not been blended with the setting agent component B finishing up on the floor and leaving a sticky uncured spot.

the flooring aware is two metal colors, red and also black pigments with a black wetness barrier. Specialists refer to this as the cash action. It's the most crucial step in the metal epoxy color application procedure. You've come this much, don't stop now! When the metallic is completely dry the decision can be made on whether to install a safety clear topcoat.

Flooring Fundamentals Explained

Themetallic epoxy layer can likewise stand up go to this web-site to high temperatures and also hot tires if applied appropriately. Are metallic epoxy floorings worth it?

Because of these variables, it is essential for you to be accurate, Metal epoxy applications aren't for the faint of heart. There are various other things to bear in mind like the temperature of the flooring when you are using the epoxy application. If it is below 50 levels it will not reasonable well.

Report this wiki page